56 lines

3.3 KiB

Markdown

56 lines

3.3 KiB

Markdown

In this repository you will find two designs for my APS H5 Autoprops, but these designs will probably fit some other models as well.

|

|

|

|

- Bearing Cap, which is an improved design of the metal caps that come with the autoprops

|

|

- Zinc Saver, which doubles the lifetime of the Autoprop Zincs by preventing them to fall off prematurely.

|

|

|

|

You are welcome to print these designs yourself, but you can also order them from me.

|

|

See [www.thefloatinglab.world](https://www.thefloatinglab.world/en/contact.html) for contact details.

|

|

|

|

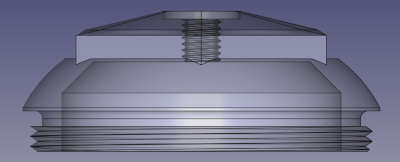

# Autoprop Bearing Cap

|

|

|

|

Bearing caps for the autoprop.

|

|

|

|

|

|

|

|

I once lost a blade, and together with the blade the bearing cap. It was bad enough I had to order new blades, and I didn't want to order a new bearing cap as well.

|

|

|

|

The advantages of my design:

|

|

|

|

- The bearing caps are much lighter than the metal ones. This increases the service life of the bearings and saildrive.

|

|

- A special tool is no longer needed, a regular socket or spanner #32 will fit on them.

|

|

- No more tool holes that get clogged up with marine growth.

|

|

- Less metal, so less consumption of the expensive annodes.

|

|

- You can just print new ones if they get damaged or lost.

|

|

- You could print each cap with a different color so it is easier to identify the individual blades.

|

|

|

|

The standard O-rings and grease plugs will fit on these caps.

|

|

|

|

|

|

|

|

## Notes

|

|

|

|

- I used PETG for printing them, as PETG is grease and water resistant.

|

|

- Make sure to dry the filament properly or it will cause leaks.

|

|

- Due to the design, use of a support interface layer filament is necessary.

|

|

|

|

# Autoprop Zinc Saver

|

|

|

|

An annoying design flaw of the Autoprop zincs is that there is too little material around the bolt holes.

|

|

So usually the material around the bolt holes is eaten away quickly and the annode falls off, while there is still a substantial amount of material in the rest of the annode.

|

|

|

|

|

|

|

|

This Zinc Saver prevents the annodes from falling off prematurely:

|

|

|

|

- By covering the bolt holes they make less contact with the sea water so the surrounding material doesn't dissolve as quickly.

|

|

- The stainless steel bolts are kept insulated from the annode. The electrical connection is now solely between the mating faces of the annode and the prop.

|

|

- Once the bolt holes start falling apart the cover will keep the annode centered and locked in place so it will stay on a bit longer.

|

|

|

|

Of course, eventually the annodes will have deteriorated so far that they will fall off, despite the Zinc Saver, but at that time the Zinc Saver will already have doubled the lifetime of the Zincs.

|

|

It is a good and responsible idea to check the annodes regularly, and to replace them before they fall off. The metal can be recycled, the Zinc Saver can be reused.

|

|

|

|

Another feature of these Zinc Savers is that they allow you to pre-install the bolts.

|

|

If you replace the zincs with the boat in the water, you will love it that you don't need to insert the bolts one by one and risk loosing them.

|

|

|

|

I print these Zinc Savers with PETG, which I think is the best material for this purpose. It takes just 2.5 grams of material

|